First off, The Garage Night episode on this is great. Check it out.

Here is my starting point.

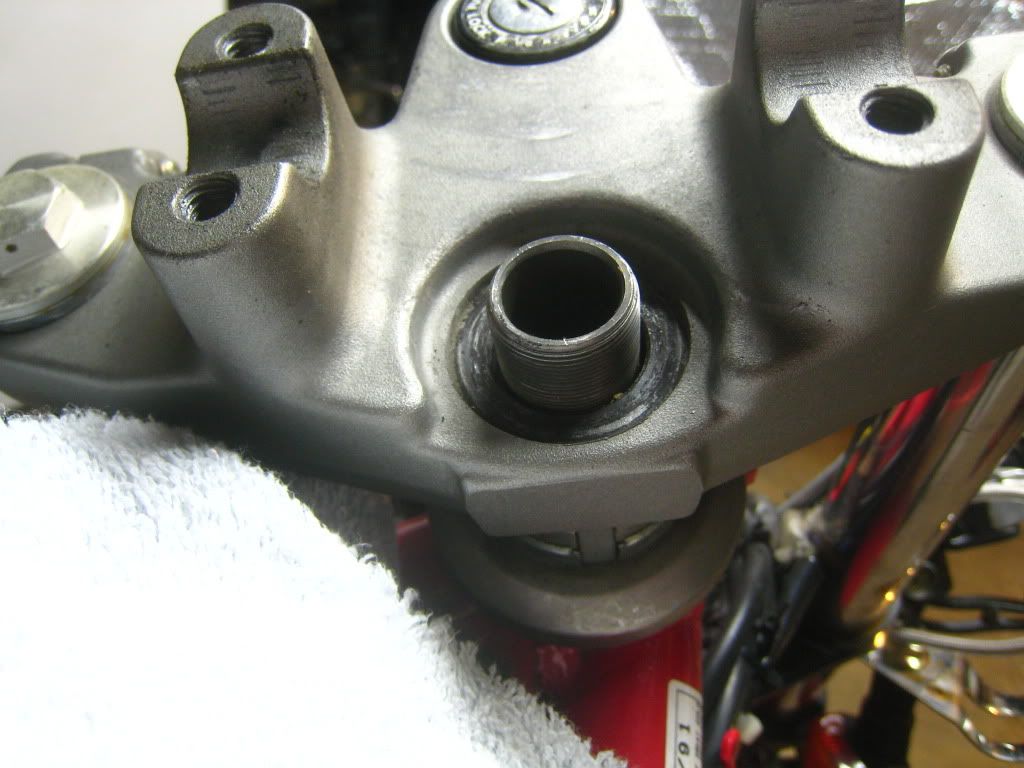

First I removed the handlebar and headlight, then removed the fork tubes. After that, it is time to take off the stem cap that's right in the middle of the top triple tree.

Once that is off, the top triple tree comes right off. Underneath the top triple tree is the ring nuts. You are supposed to use a C-spanner on these, but you can use a screw driver and a hammer to tap them both off.

There should be a rubber grommet between the 2 nuts. Once the 2nd ring nut comes off, the stem and lower triple tree should fall out, so be sure to catch it.

Now you have to remove the races and the lower bearing on the stem. The lower race was pretty easy, there are a couple notches in the head tube that allow a punch to catch on the lip of the race and pop it out easy.

The top race is not so easy. There are no notches, and I could not get my cheap harbor freight punches to catch it (they are soft steel, so deformed and dulled). My solution was to take my dremel and a grinding bit and make a shallow notch in the head tube, just enough to be able to catch the lip of the race (shown below).

The "notch" here is really shallow. I didn't need much to be able to catch the lip of the race.

Next is removing the bearing from the stem. The Haynes manual says to take a chisel and tap it between the stem and bearing, but this is a bad idea and will damage the stem as it's soft steel. Take a chisel and put it at an angle digging into the bearing and tap it off.

Here is my old race showing the wear grooves.

It's actually not bad. I probably could have done without replacing these, and just tightened them up, but since I have come this far, I figured I'd replace them anyway since I have new ones.

I have it put back together now, except for the handlebars and headlight. I don't have a C-spanner, so I wasn't able to torque it correctly, I just kind of guessed for the procedure in the Haynes manual (tighten, then loosen, then tighten lightly, manual gives specific torques). I will look for a spanner, but if any of you have experience with this, or other ideas on torquing this correctly, I'd love to hear it.

I'll update this thread when I finish up.